Get Familiar with our MACU-Trac Cooling Tower Chemical Controller

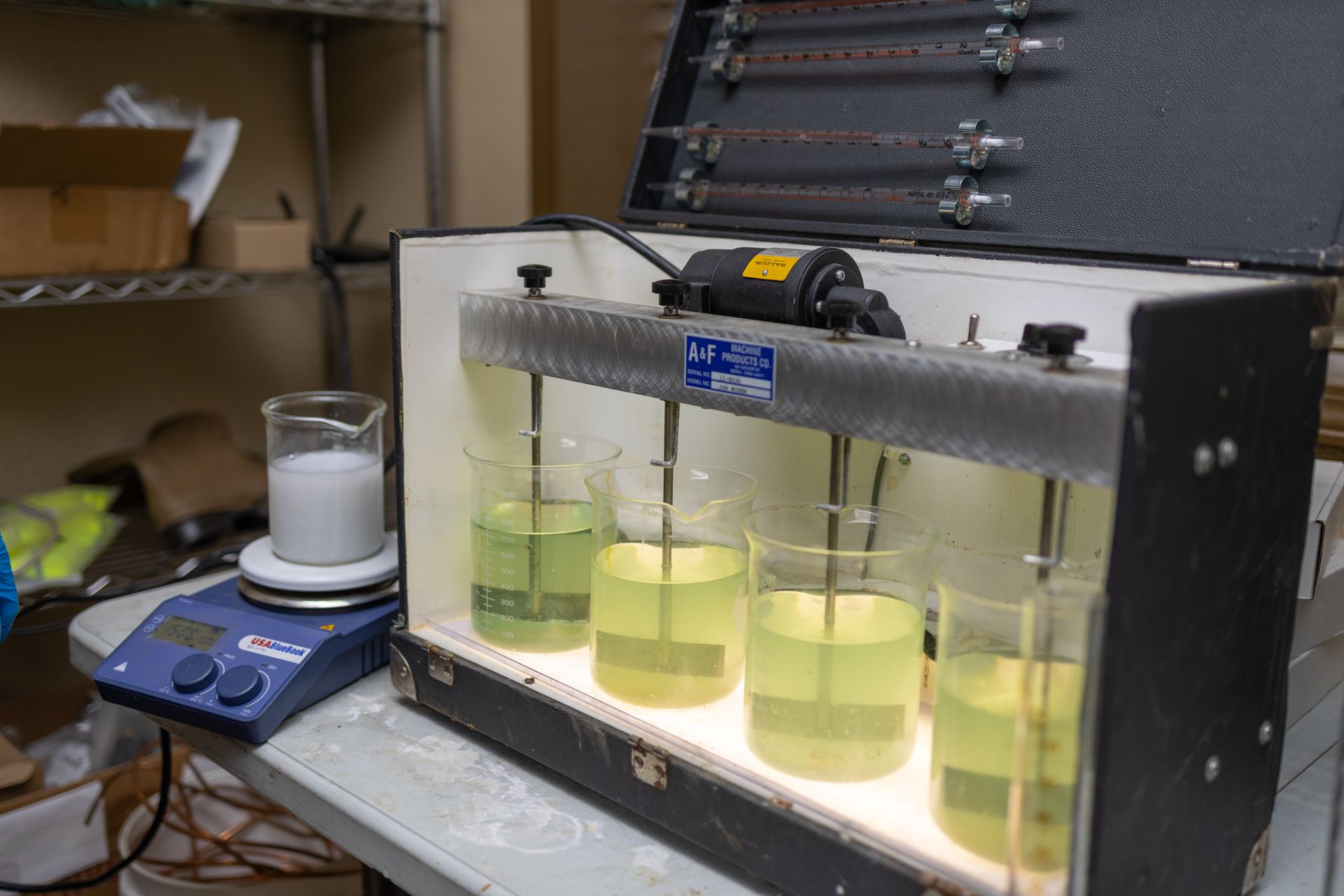

The MACU-Trac cooling tower chemical control system automatically adjusts the corrosion inhibitor and oxidizing biocide to ensure the chemical’s are 100% correct at all times.

Traditional chemical controllers operate on timers. The technician who sets up these controllers assumes what the feed make-up water’s flow rate and chemistry is. With that information, the entire chemical strategy is programmed into the chemical controller plus a margin of error. Therefore, at best, the tower is taking more chemicals than needed.

The problem is the feed make-up water’s chemistry changes per season, if anything mechanical changes in the system (like a leaking blow-down valve or system maintenance), a system cleaning, or numerous other issues that are normal to happen, the chemistry is off causing damage, wasting chemicals, and cost money.

WHERE THE TECHNOLOGY CAME FROM

Nalco is a very large chemical company. One of the reasons why they grew so big is because they were the first to come up with this technology. Throughout the years, their utility patent would expire and they would change something to keep the patent. This is why their automatic systems, that do the same thing as the MACU-Trac are very large, expensive, and complicated.

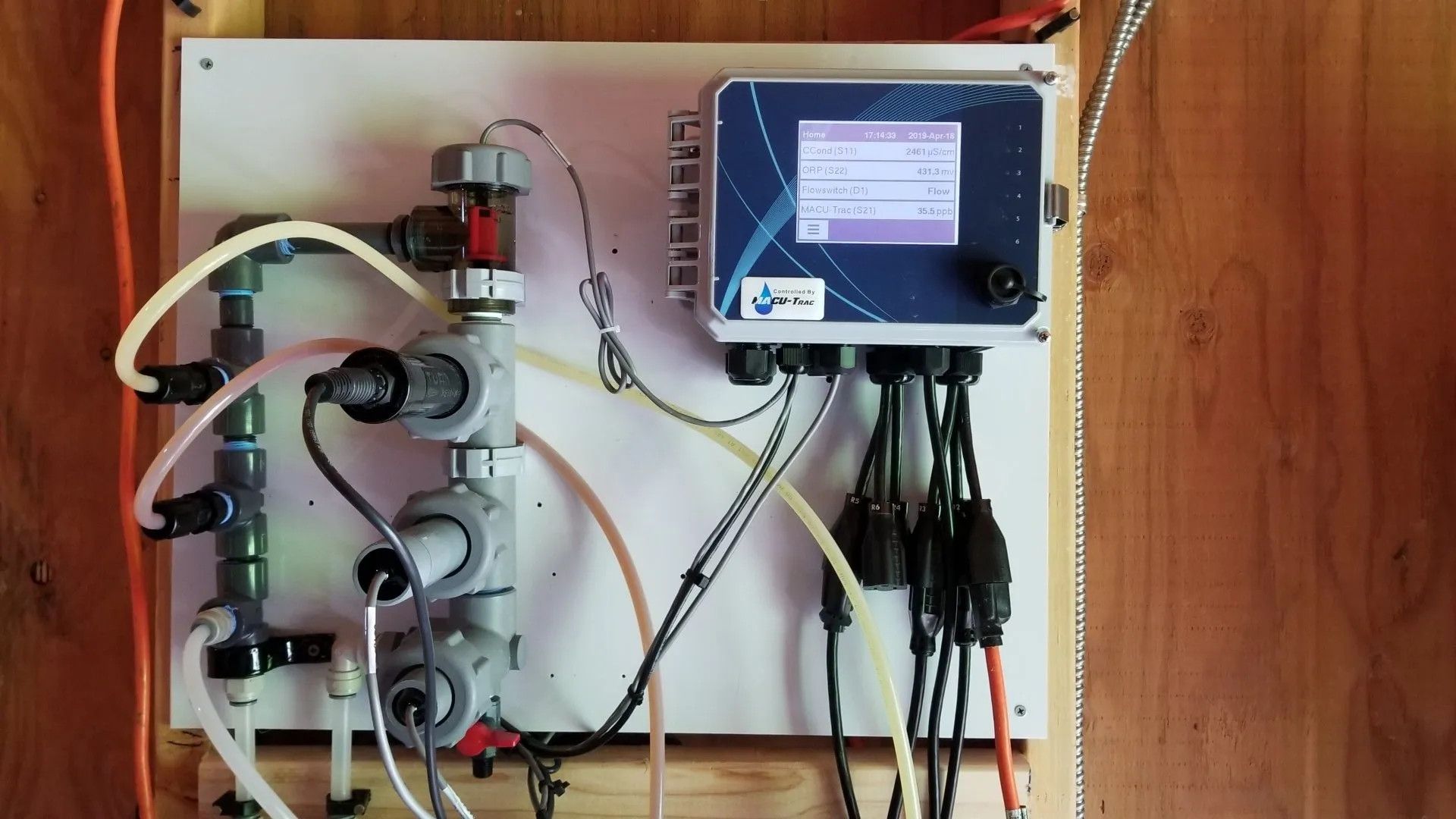

MAC Water Technologies replaced this complicated system with just three probes and a small basic controller.

MACU-Trac’s three probes are:

- TDS (Total Dissolved Solids) – similar to everyone else’s.

- MACU-Trac probe – measures the inhibitor.

- ORP (Oxidation Reduction Potential) – measures the oxidizing biocide; Chlorine for example.

The MACU-trac uses the three above probes to automatically adjust the chemical pumps to maintain the exact, not more and not less, chemical dosing needed for the most economical asset protection available on the market.

WHEN TO BE CAUTIOUS

If the contract with your chemical provider is a set price, be very cautious and spot check the monthly reports every season.

In the Spring, pollen and other dirt is high in the air causing the need for more biocide.

In the summer, the TDS of the water increases causing the need for more inhibitor.

In the Fall, the pollen and other dirt is high in the air causing the need for more biocide plus the TDS of the water increases causing the need for more inhibitor.

In the winter, the water table is typically at its lowest causing the TDS to be high causing the need for more inhibitor plus there’s little pollen and dirt in the air causing the biocide to be too high which will corrode the pipes and heat exchangers.

If your contract with your chemical provider is a fixed price, be VERY cautious towards the end of their contract because they will back off the chemical dose if they run out of profit. This is the number 1 reason why we get hired to replace chemical contracts.

Why The MACU-Trac Stands Out

The MACU-Trac ensures the chemicals are 100% correct at all times. This system has an aggressive return-on-investment because no chemicals are wasted and the equipment is properly protected. The engineering specification section is 232500 HVAC Water Treatment – Cooling Towers.

Need More Help? Contact Mac Water Technologies!

Consulting service by the engineers at MAC Water Technologies can help save you both time and money. Our proven technologies and professional technicians can provide the answers and solutions you're looking for when it comes to water management. Call us today for more information!