Understanding Granular Activated Carbon Water Filters

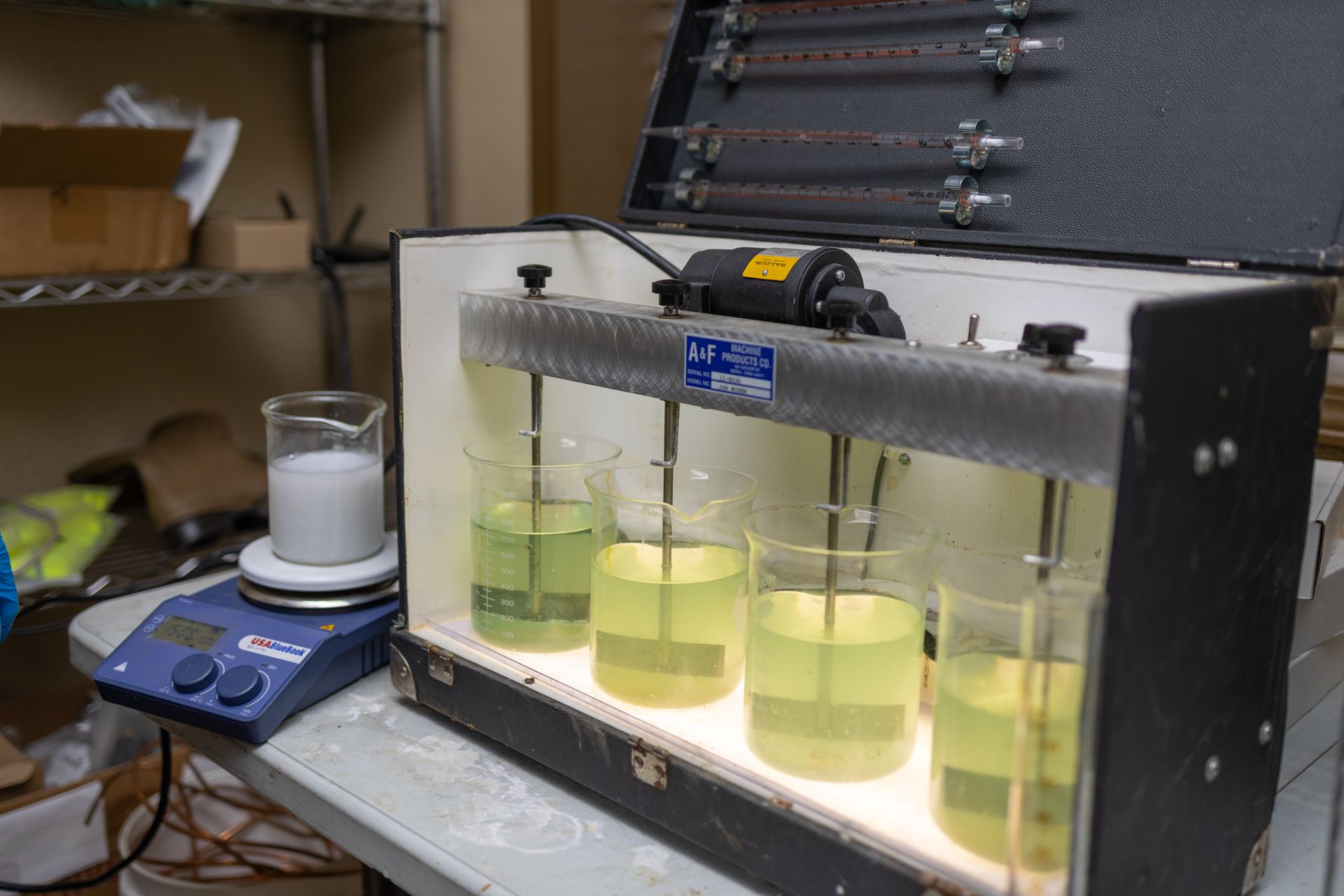

MAC Water Technologies uses carbon filtration for MANY applications. Our standard MACU-Clean carbon systems for Chlorine and Chloramine removal use Coconut Grade Carbon at a 5-minute contact time. Our AquaDrop technology uses High Catalytic carbon for groundwater pesticides, VOC, certain organics, and other high catalytic removal needs at a longer contact time.

For food and beverages we use other types of carbon at different contact times to create a color or flavor profile our customers are looking for. It is very understandable why we receive so many questions about carbon. This blog discusses the basics with the help of our friends at Liberty Carbon.

What Is Activated Carbon?

Granular Activated Carbon (also known as Activated Charcoal, GAC, PAC or Vapor depending on its application) is not to be confused with Carbon Black. Activated Carbon (AC) is a very simple yet very technical product that can be used for water filtration. It is commonly used for removing contaminants from a source stream (liquid or air) through a process known as adsorption.

Merriam Webster says Adsorption means "the adhesion in an extremely thin layer of molecules (as of gases, solutes, or liquids) to the surfaces of solid bodies or liquids with which they are in contact." Activated Carbon is created typically by steam activation or acid washing. Most of what we use is steam activated because acid washing requires our customers to flush the carbon before using. The steam or acid creates or opens a pore structure inside the carbon particle and thus creating a pathway for the source stream to travel and the contaminants to be adsorbed onto.

In a quality activated carbon product the volume inside the pore structure is enormous. You would never know it by looking at a small pile of carbon particles but 3 grams of AC can have enough pore volume (or surface area) to cover a football field. All that surface area is what makes AC such a great filtering media.

What Is Activated Carbon Made Of?

Activated carbon is typically made from Coconut Shell, Select Grades of Coal or Wood Based Materials. Coal based carbon is made from bituminous or sub-bituminous coal which can either be direct activated or re-agglomerated. Re-agglomerated is far superior for reactivation purposes whereas direct activated carbon is typically disposed of after use.

In addition, AC is also made from coconut shell or wood based materials like walnut or hard wood. Coconut shell AC is a very good quality product and can be reactivated as well. A vast majority of our Chlorine and Chloramine removal uses Coconut grade carbon, especially before reverse osmosis systems, and we keep our prices down by purchasing in bulk.

AC is evaluated on several properties that determine it's quality. First is what is called the Iodine Number which equates to the adsorption capacity of the carbon meaning how much contaminants or organics that the carbon will adsorb or, sequester inside the pore structure before the carbon is depleted or "spent."

Different carbon base materials are better suited for different applications. Coal based AC has more Macro and Meso-pores which lend itself to larger organic compounds whereas coconut AC has more Micro pores which work better for smaller organic compounds, again making it the preferred carbon for reverse osmosis pretreatment.

Adsorption Rate

Activated carbon can usually adsorb between 10-20% of its beginning dry weight in contaminants or organics. This means that 100 dry pounds of good AC should remove approximately 10 to 20 pounds of contaminants before it is spent or exhausted. It is important to note here that some things are easier to remove with carbon than others. Some things will be removed faster and in higher concentrations than others. This is all dependent on what you are filtering and is one of the areas that can become very technical; please allow the engineers at MAC Water Technologies to help in your selection.

Hardness Number

Another important property of AC is the "Hardness Number," which is a measure of how well the carbon will hold up (or not become smaller particles) under transfers, backwashing, reactivation or other handling. The higher the hardness number, the less likely the AC is to degrade in size. Coconut and re-agglomerated carbons both have high hardness numbers and direct activated coal carbon and wood-based carbons are softer and thus have lower hardness values.

Vapor Phase Carbon is typically specified by what is called the CTC number, not iodine, and that is a whole different discussion.

Particle Size

Particle size is another important aspect of carbon selection. In a liquid phase application, the most common sizes are what we call 8x30 or 12x40 mesh which allows the particles to interlock as the liquid flows through the carbon bed and forces the liquid to come into contact with all those pores mentioned earlier.

You want to have the right particle size to accommodate the proper flow rate and contact time for the fluid you are treating. There are other sieve sizes for AC that may be the right fit depending on the specifics for each application.

Reactivation

In certain circumstances, spent carbon can be reactivated under an oxygen deficient process that will volatize the organics or contaminants that are bound up in the pore structure of the carbon and then those contaminants are thermally destroyed. When done properly, the contaminants are removed without consuming or burning up the carbon particle which opens up the pore structure again and the carbon can then be re-used.

We do this on a closed loop cycle where specific customers only get back their sourced material or, we can also supply what

we call "pooled" react which is carbon that has come from various sources without segregation and reactivated in a pool fashion. This is typical with industrial grades of carbon.

Call MAC Water Technologies to Maximize your Water Filtration Solutions

We know that is probably way more than you ever wanted to know about granular activated carbon, but even when keeping it simple, it's clear how important it is to understand the way activated carbon works. There is a lot that goes into the proper product selection, but the uses are as broad as the variances.

For more information on our water filtration tech and products, contact MAC Water today! We're happy to walk you through all of our available solutions to find the one that best fits your needs.