Common Causes of Sanitation Problems in High Purity Water Systems

MAC Water Technologies will often consult with businesses on how to reduce sanitation problems in high purity water systems. There can be several things causing this issue, and it’s important not to cut corners when it comes to your water system. Each piece of equipment plays an important role in ensuring the cleanliness and safeness of your water. Sometimes it just comes down to understanding how each component works and how to identify these issues.

What is a High Purity Water System?

A high purity water system is a type of filtration system that is designed to remove impurities from water. There are a variety of different types of high purity water systems, but they all share the common goal of providing clean, safe water. However, if there’s something off with any part of your high purity system’s chain of process, it can throw the system’s efficiency off. You need to take care of each component properly.

When a piece of the system is off, one of the most common problems that can occur in your high purity water system is contamination. This can happen when impurities such as dirt, bacteria, or other contaminants enter the system. If these contaminants are not removed, they can cause serious problems for the system, including clogging filters and other equipment. MAC Water can help identify the source of these contamination issues and fix your sanitation problems.

Top Causes of Sanitation Problems

UV System Issues

Ultraviolet (UV) ballasts and electronics are designed to work together. ALWAYS use OEM parts on a UV system. Non-OEM lamps will not produce the same UV wavelengths, will not last as long, and will pull more amperage which lowers the service life of your $1,000-plus ballasts. For example, UV intensity monitoring sensors monitor UV light, not 254 nm UV light. It’s important to understand the parts of your UV system to ensure they are operating at the highest level possible.

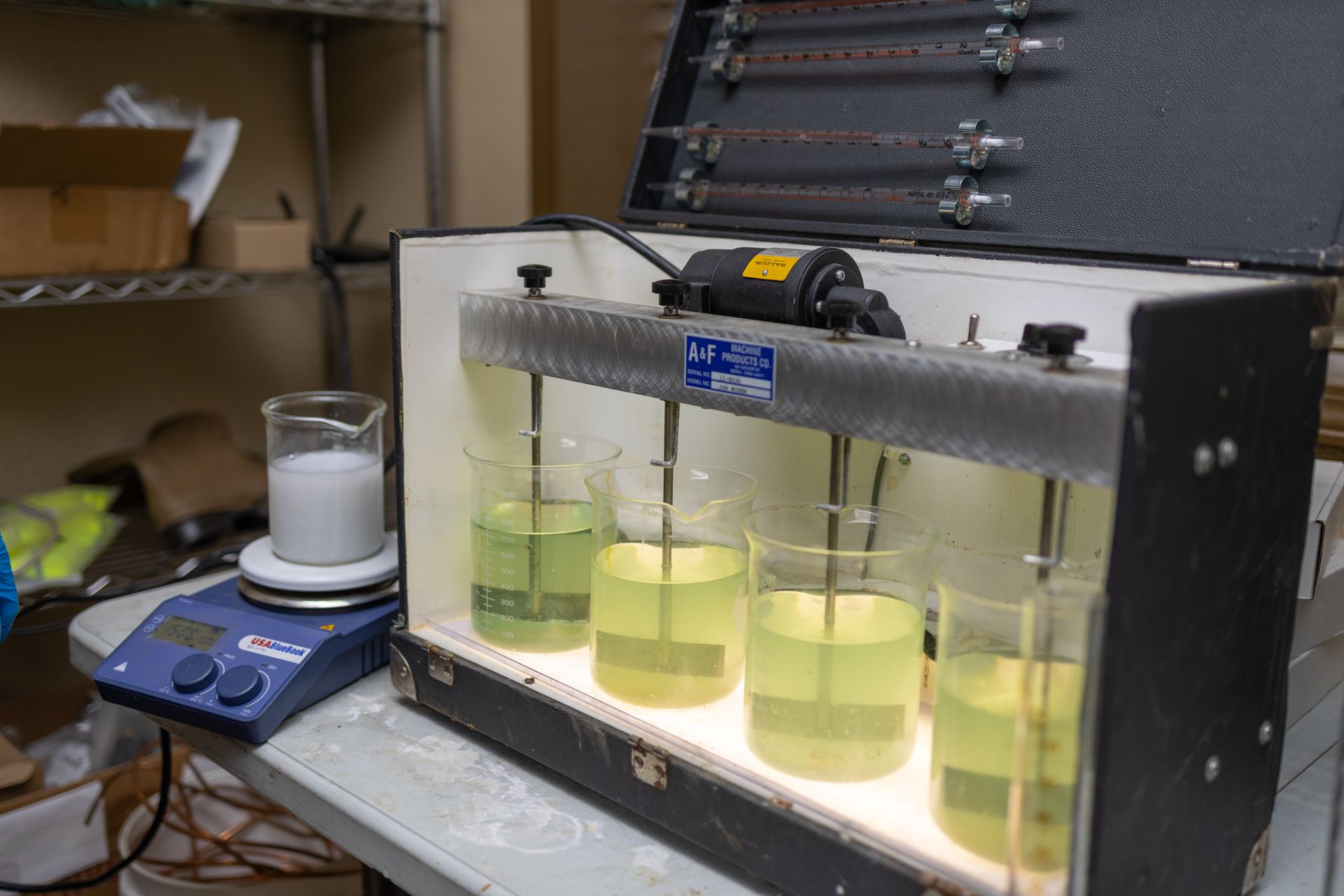

Polishing Filters

Using cheaper polishing filters can be a poor choice. Often-times the originally designed filter cartridge was changed by the purchasing department. When it comes to your high purity water system, cutting corners is hard to do and you need the best equipment. Polishing filters are often used in high-purity water systems, such as those used in the semiconductor industry, to ensure that water is free of impurities.

Flow Rate

Having a low flow rate in piping will allow bacteria to attach themselves to the pipe walls and grow biofilm. Biofilm is a layer of living organisms and their excretions that form on surfaces. In high purity water systems, biofilm can form on piping and other surfaces, leading to contamination. If you do not have a high enough flow rate, you may need to increase the size of your piping. Another way to improve flow is to add more return points so water can travel in a loop back to the pump. This will also help reduce any stagnant areas where bacteria can grow.

Pretreatment

Improperly maintained prefiltration equipment may affect downstream sanitation. Dirty or fouled pre-filters can lead to a high concentration of particulates in the system, which can provide sites for biofilm growth.

NEED MORE HELP?

Consulting services by the engineers at MAC Water Technologies can unlock the peak potential of your high purity water system. Mac Water Technologies has invested time and energy in creating solutions for clients all over the world. Any project, large or small, our experts can handle it efficiently and within budget. Not only does MAC Water source OEM parts exclusively for your own needs but we also have some of our very own in-house products that change the game in water treatment. Contact MAC Water today for a proper solution for your water or water system!