How To Keep Carbon Beds from Producing Too Much Bacteria?

Carbon beds grow bacteria. Period. That’s what they do! This is the reason why you typically want to install carbon filters last in a series of filters. For example, install carbon water filters AFTER softeners, etc.

Carbon beds can produce too much bacteria if they are not maintained properly. If the carbon bed is not replaced often enough, the bacteria population will start to grow again and can reach levels that are higher than before the carbon bed was installed. However, there are many steps you can take to reduce bacteria growth and keep your carbon filters operating smoothly.

If you are a food company, pharmaceutical company, and especially if you have TOC level restrictions, this article is for you.

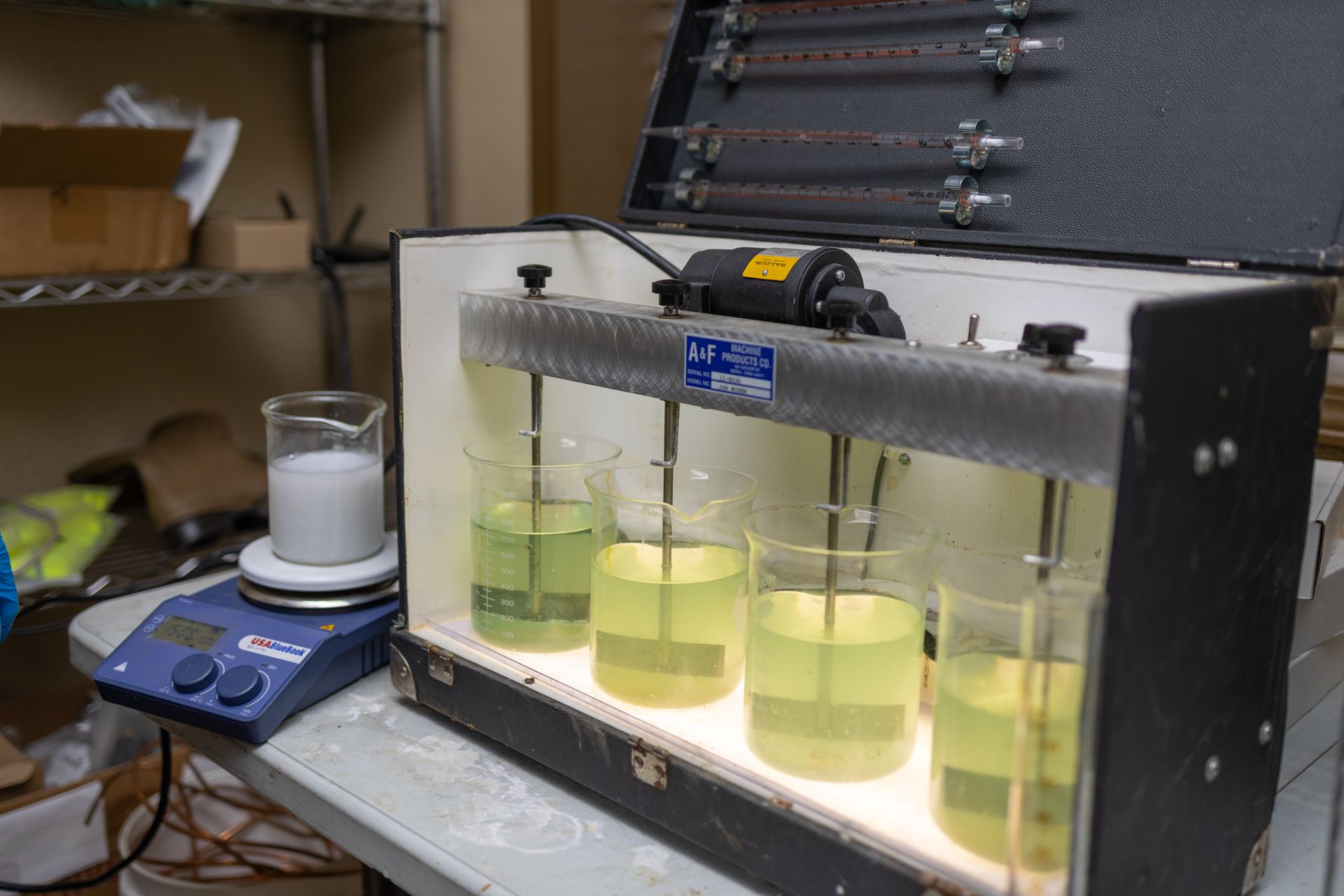

What Are Carbon Beds?

Carbon beds are used in a variety of industries for their specific water treatment needs. They are most commonly used to remove dissolved organic carbon (DOC), taste, and odor from water. Carbon beds can be made from different types of carbon; such as bituminous coal, lignite, wood, coconut shell, and anthracite. The carbon bed must be able to adsorb the target contaminants from the water while allowing the water to flow through at an acceptable rate.

How Do Carbon Beds Work?

Carbon beds work by adsorbing contaminants onto the surface of the carbon particles. The carbon bed must be able to contact all of the water that contains the contaminants. If the carbon bed is unable to contact all of the water, the carbon filter will not be effective or operate like it should. The carbon bed must also be able to flow water through at an acceptable rate. If the carbon bed is too small or does not have enough void space, the water will not be able to flow through properly. When your carbon bed is obstructing flow or can no longer adsorb contaminants from the water it will have to be replaced.

Strategies to Reduce Bacteria

MAC Water Technologies understands that there are many options to help slow and reduce bacteria growth in your carbon filters. Here are a few ways you can help reduce bacteria in those carbon beds:

Ultraviolet Lights/Rays

Ultraviolet (UV) lights are a very effective way to reduce bacteria loading. The idea is if bacteria can’t get to the carbon bed then bacteria can’t grow in a carbon bed. This is a logical maneuver. However, we think putting in UVs AFTER the carbon bed may be a better fit for the money.

Backwash

Make sure the backwash flow rate and time is accurate for your system's application. Drain Line Flow Controls (DLFC) on carbon beds are often selected as a rule-of-thumb versus what the actual water pressure and plumbing situation calls for. Always be sure to double check your set-up or call MAC Water Technologies with any questions.

Steam

Sanitizing your carbon bed with steam is a solution often used on high end applications. While steam cleaning is very effective, it is also more of an old school technique and can be expensive.

Hydroxyl Radicals

During downtime or while in a cleaning cycle, recirculating in backwash with a side pump and injecting Hydroxyl Radicals is not only a very effective way of sanitizing carbon beds, it is also extremely efficient and does not waste any water.

Commonly used Hydroxyl Radicals include:

- Ozone

- Hydrogen Peroxide + Silver

- Chlorine Dioxide

- Manganese Greensand

- Potassium Permanganate

- Aquaox

HAVE QUESTIONS?

MAC Water Technologies has global experience in consulting and integrating alternative cost-effective solutions. We can help you choose the best treatment method for your needs and provide ongoing support to ensure your system operates effectively. Contact MAC Water Technologies today to learn more about our services and solutions.