How To Reduce TDS In Wastewater

Total dissolved solids (TDS) is a measure of all the molecules contained in a liquid; TDS is often synonymous with dissolved solid matter. High levels of TDS may lead to water that appears cloudy and feels slippery, like soap or detergent. As TDS increases, the taste of drinking water may change due to an increasing number of non-nutritional ions dissolved in it. The recommended limit for TDS content in tap water is 500 mg/L (usually expressed as 500 ppm).

The most common source of high total dissolved solids (TDS) concentrations in tap water is an underlying aquifer containing significant quantities of minerals which are easily dissolved. This can be naturally occurring or result from anthropogenic activity such as mineral extraction or surface water impoundment behind dams. Dissolved TDS may also come from household or industrial wastewater being discharged directly into waterways, resulting in direct addition of TDS to the receiving stream.

How Do You Reduce TDS In Wastewater?

There are several basic methods used to remove TDS from water: chemical coagulation, reverse osmosis (RO), demineralization or deionization (DI), and electrodeionization (EDI). Some processes use more than one of these technologies in sequence while some companies have developed proprietary technologies that accomplish both RO and DI simultaneously. Although each technology has its own strengths and weaknesses

In order to determine which method(s) are right for you, there are a few questions you should ask yourself before designing a system.

What Concentration Must My Final Effluent Be?

This is specific to your facility, but it is important to remember that the EPA does have discharge standards. Be aware of these standards and try not to exceed them. If you are planning on discharging water into a public system or well then be aware of their limits too!

What Is The Best Way Of Reducing TDS In My Wastewater?

It is important to recognize, ion exchange, which typically uses sodium as a solvent, does not reduce TDS, hence the term “exchange”. These systems exchange one part of one ion for another part of a different ion which does not reduce ions.

By reducing the total dissolved solids you will also be reducing your filtration costs and optimizing treatment chemicals. Ions such as calcium, magnesium and iron are typically what cause scaling on heat exchangers and pumps, so a reduction or removing by “exchanging” less corrosive ions can have a significant impact on the life of your equipment.

How Does Reverse Osmosis Work?

In general, membrane filtration processes such as reverse osmosis and nanofiltration are often used for treating water and wastewater where TDS concentrations need to be less than 50 ppm (mg/L). It is only with the use of these technologies that it is possible to reduce total dissolved solids from wastewater below 10 - 20 ppm (mg/L).

Reverse osmosis, or just RO purification, is a process that uses pressure to force pure water through a special organic membrane only allowing H2O to penetrate, which filters out particles and contaminants that make the water less safe for consumption. Basically, one side of the membrane is pure water and the other side of the membrane has all of the dissolved solids, separating impurities from the water source to purify the end result.

What Are Some Advanced Methods Of Filtration?

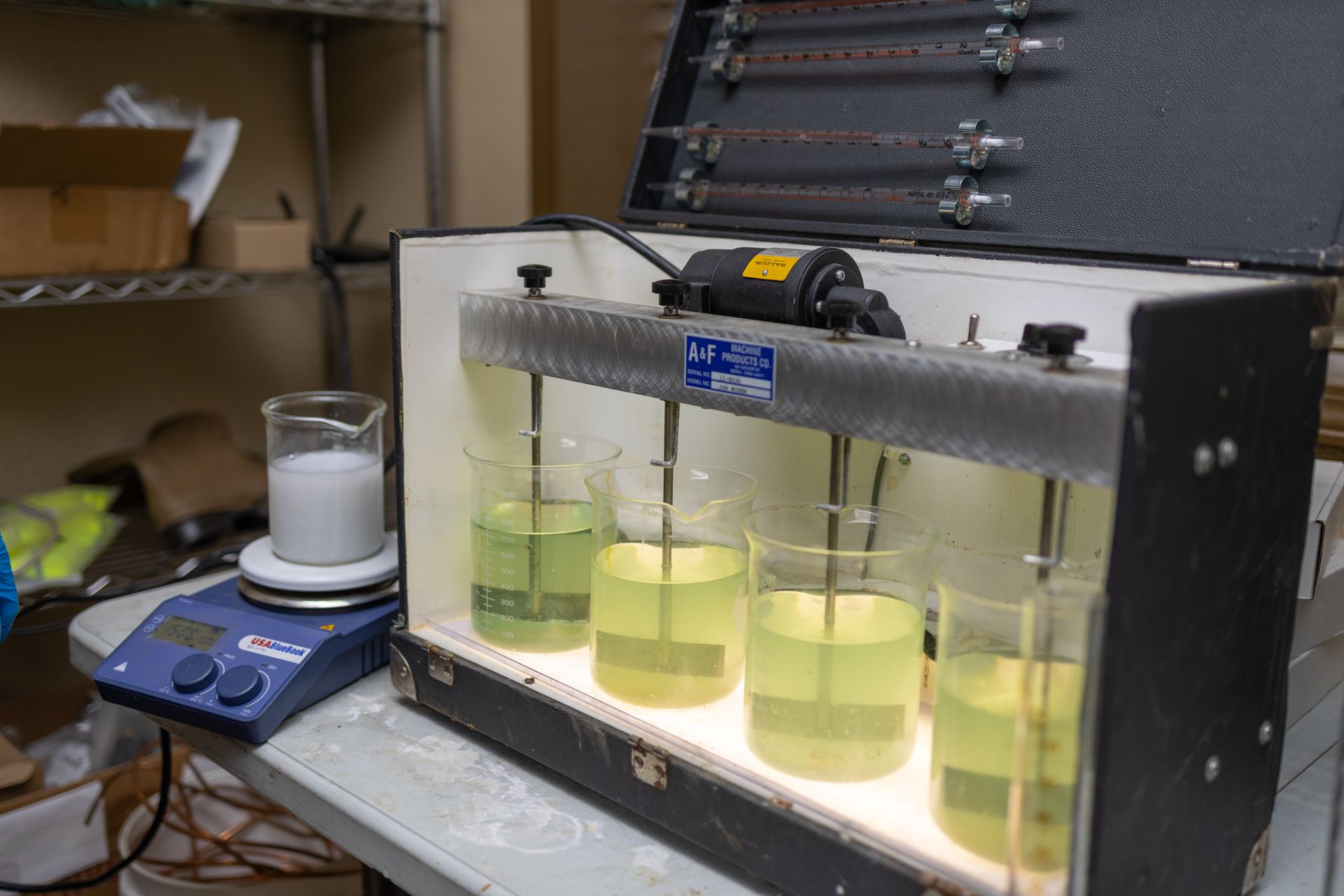

Chemical Coagulation

Chemical coagulation is typical in wastewater applications. Basically, chemicals remove the dissolved ions into particles that can be filtered out which lowers the total dissolved solids count. Ions bond to each other chemically and form molecules such as sodium hydroxide (NaOH), sodium carbonate (NaCO), calcium hydroxide (Ca(OH)), and calcium carbonate (CaO). These substances are removed with the sediment filters.

Demineralization or Deionization (DI)

This is another type of waste treatment that removes ions from drinking or wastewater. There is no membrane in DI, but rather used special resin beads that have an ionic charge on them. Ions in the water attach themselves to the resin and are removed from the water via this ionic charge.

Electrodeionization (EDI)

Chemical-free deionization methods use electricity to constantly clean the ions off the resin beads described above. The concept is the electrical field clears the ions off the resin beads at the same rate as the resin beads attract and remove the ions from the water. This method requires electricity to function; however, chemical-free deionization is more environmentally friendly than chemical means.

Reduce Your Impact and Call A Professional

The experts at MAC Water Technologies are ready to help your business create less of an impact on the planet. Call today to get help with all of your high purity and wastewater needs!